Wish I could show more work for the time spent this past week or so.

Anyway, I came across a problem of the instrument panel covers front contours not matching the windscreen line. No matter how I moved it around I just could not get it to fit properly! Time for a trip to see the machine herself and see where I went wrong or what I was missing.

As soon as I saw it I realised 2 things:

1. There was a recess through the centreline of the cover that the centre windscreen frame passed through

2. There was a panel between the windscreen and the cover(just below the frame line......phew!

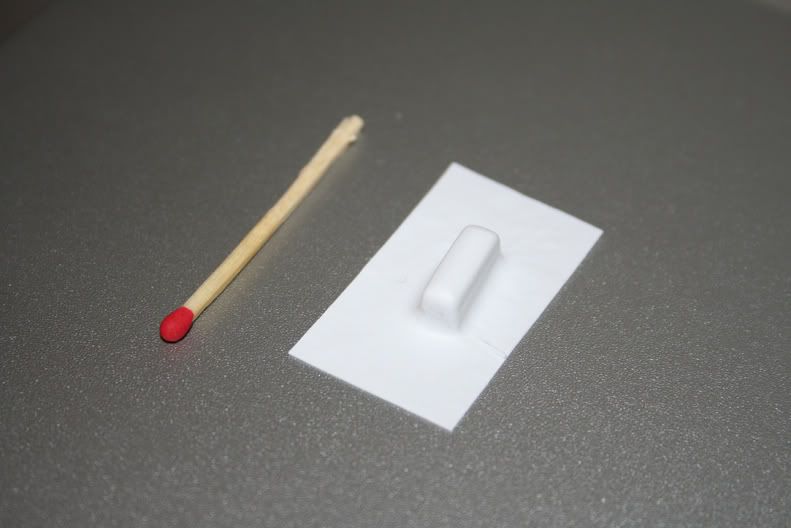

This entailed me fitting a 10 thou piece of card around the top edge as I have cut the lower windscreen line down to the frame line to compensate for the new windscreen fittment and replacement frame.

Now the front edge of the panel cover is too big and needed cutting right back and a constant trimming was needed for a nice fit. This took a fair bit of time as I had to make sure it was at the right height.

I wasnt going to glue this in but after many nights of fitting & trimming I decided that I really needed to if I was going to have a nice fit. It is going to slightly complicate things for me down the track, but I dont think I had any choice for the best result.

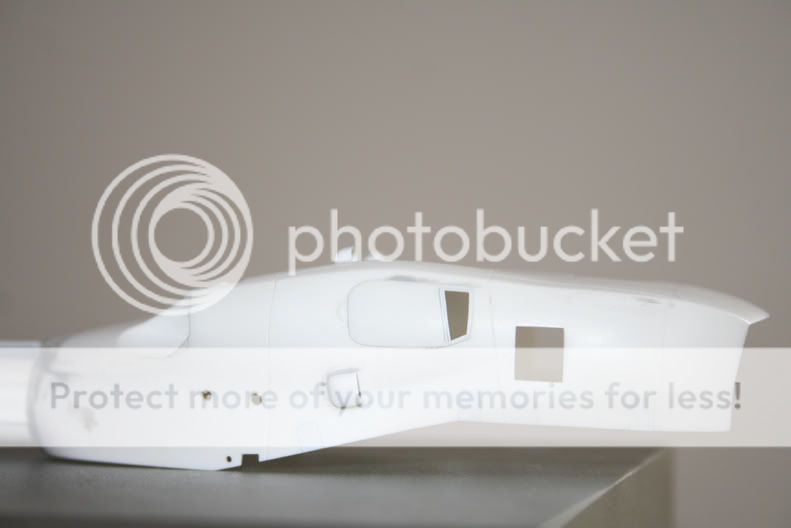

I jigged everything up and glued it in finally!

Then Mr Surfacer was brushed around the edge, I am really happy with how it turned out.

you can see in this photo the centre ridge has also been added.

I had to remove the temporary windscreen centre frame as this was only added earlier to line things up.

Here are a few quick pics before I go to bed

What do you think.....did I get it right?????? I hope so, I have spent so long on it I cant tell anymore! There may be a little tweaking here and there, but on the whole I think it is pretty close.

Excuse the photos...its getting late......again

Cheers and thanks for taking the time to look in.

Anthony

,

,